Reconditioning Extruder / Injection Moulding Machinery Parts

Plastics manufacturers and related industries enlist our company to recondition extruder and injection moulding machinery parts for good reason.

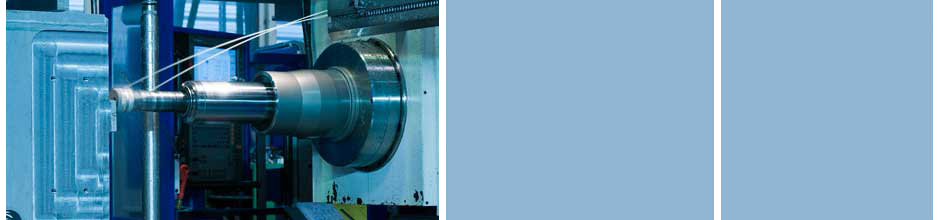

Wagma Engineering are dependable plastics industry engineers that specialise in the Reconditioning and Repair of Injection Moulders / Extruders - Screws, Barrels, Tie Bars and Smear Heads for injection moulding, blow moulding and extrusion machinery equipment and machinery.

It may not always be viable to manufacture new parts for your machine so at Wagma the first thing that we look at in the assessment of the parts that you are having problems with is whether or not the parts are suitable to be reconditioned. In the case of a Barrel and Screw set we would look at how much wear is in the barrel and whether or not it would be viable to hone out the damage and reclaim a new slightly larger barrel size, then if it is a Nitrided Barrel or a Bi-metal Barrel in the case of a Nitrided Barrel once honed Wagma will then nitride the Barrel so that the bore is as it was when new just a slightly larger bore. With a Bi-metal Barrel we just have to make sure that the wall thickness of the Bi-metal coating is still sufficient enough to be still in place once the wear has been removed. This leads us to the screw the screw is assessed along with the barrel to make sure that the flights are still wide enough and not to badly worn making it suitable for reconditioning. The steps to recondition the screw are to prep machine the outside diameter of the screw, remove the chrome if applicable, weld up using grade 12 Stellite, proof grind the screw then polish the screw and touch up any low spots that may sometimes occur, chrome is next to go back onto the screw followed by a polish & a final grind to suit the new barrel size. Note: Not all screws have chrome on them or are reconditioned with chrome on them it is a case by case scenario.

In the case of a injection screw & barrel set the smear head is also an integral part of the running and process so once the new barrel size is achieved the check ring is made to suit the new barrel size so that you can still get a cushion for your shot and process the plastic correctly.

Wagma Engineering in Melbourne has reconditioned extruder and injection moulding machinery parts for the plastics Industry since 1975. Our Injection Moulders / Extruders - Screws, Barrels, Tie Bars and Smear Heads manufacturing and injection moulding / extruder parts reconditioning company is committed to providing unsurpassed General Engineering, components manufacture, Breakdown Repairs and specialised precision engineering for Plastics Manufacturers and other industry.

Extruder Injection Moulding Machinery Parts Reconditioning for Plastics Industry Equipment - Wagma Engineering Melbourne, Australia